Home / New Equipment / Autonomous Mobile Robots / OTTO 100

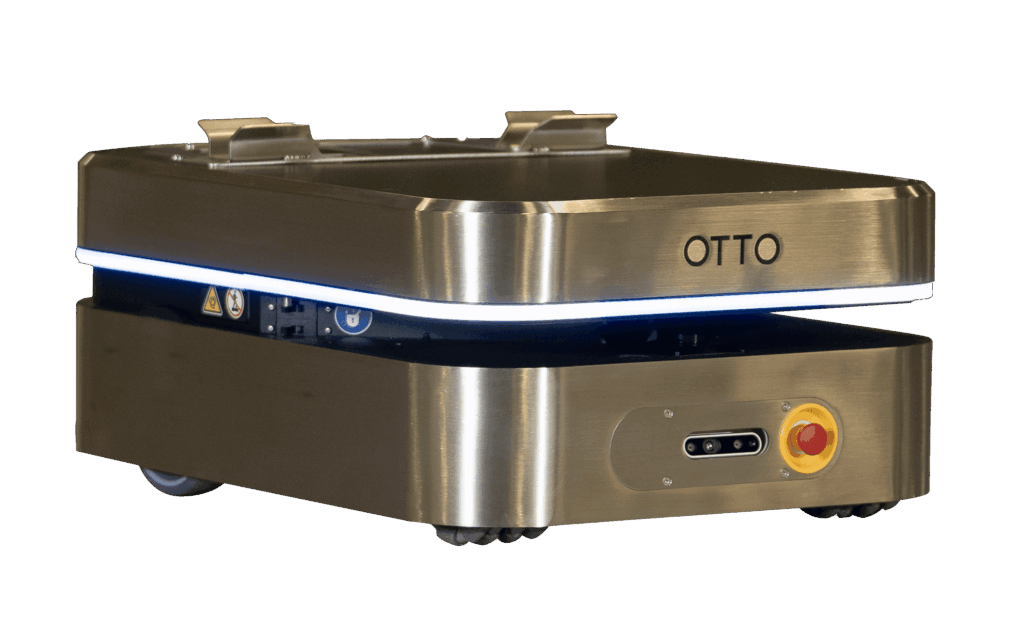

OTTO Motors OTTO 100

Autonomous Mobile Robots

OTTO 100 is an industrial strength autonomous mobile robot (AMR) that safely moves boxes, bins, carts and other lightweight payloads to increase materials handling throughput in factories and warehouses.

| Battery Capacity | 35 Ah |

|---|---|

| Battery Charging Options | Autonomous Opportunity Charging (Default), Manual Charging |

| Battery Life | 10,000 full charge cycles |

| Battery Voltage | 26.4 V |

| Charge Time (10% to 90%) | 18 mins |

| Communication | WiFi 2.4 / 5 GHz (802.11 a/b/g/n/ac) |

| Dimensions | 740 x 550 x 308mm (29.1 x 21.7 x 12.1in) |

| E-Stop | 2 E-Stops (front and back) + user E-Stop circuit interface |

| Ground Clearance | 6 mm (0.25 in) |

| Integrated Lift | 62 mm (2.44 in) stroke, 150 kg capacity |

| IP Classification | IP20 |

| Manual Control | Guided autonomous control available via OTTO software interface |

| Mass | 107 kg (236 lbs) |

| Max. Capacity | 150 kg (331 Ibs); includes payload, attachments and cart, if any |

| Max. Charge Rate | 98 A |

| Max. Docking Speed | 0.3 m/sec (0.7 mph) |

| Max. Humidity | 95%, non-condensing |

| Max. Speed | 2.0 m/sec (4.5 mph) |

| Max. Turning Speed | 1.25 rad/sec (75º/sec) |

| Min. Aisle Width (One Way) | 1099 mm (43 in) |

| Min. Aisle Width (Two Way) | 1975 mm (78 in) |

| Power Interface | 26.4 VDC, 12A max, unregulated |

| Runtime (10% to 90%) | 6 hr |

| Safety Interface | 2x E-stop extension, 8x Digital IO, 2x dry contact relays, 1x Auxiliary Monitor Contact |

| Sensors | Hokuyo Safety Laser Scanner, 3D Camera with 90° front coverage, ToF rear sensor with 90° reverse coverage, Inductive cart detect sensor |

| Signal Interface | 1x Ethernet, 1x USB 3.0, 1x serial RS-232 |

| Standards Compliance | ISO 12100, ISO 13849-1, ISO 3691-4, ANSI/RIA 15.08-1, ANSI/ITSDF B56.5 FCC Part 15 Subpart B, ICES-003, ICES-002 |

| Suspension | Fixed, rigid |

| Temperature | 20° to 40° C |

| Traversable Gap | 13 mm (0.5 in) |

| Turning Radius | Turn in place |

- Designed for quick setup, OTTO 100 can start moving materials in a matter of minutes. It seamlessly scales to integrate with industrial workflows, through flexible APIs, using the industry’s most powerful enterprise fleet management software—OTTO Fleet Manager.

- Equipped with the latest laser and 3D camera sensors, OTTO 100 is smart enough to operate autonomously even in the most dynamic manufacturing environments, and safe enough to work alongside people.

- From line-side delivery to work-in-progress transport, OTTO 100 can quickly switch from transporting carts to moving racks. It’s versatile enough to handle a wide range of person-to-person workflows.

- With a rugged all-metal body construction, rocker-style suspension and best-in-class electric powertrain, OTTO 100 is built to perform in the world’s toughest manufacturing environments year after year.